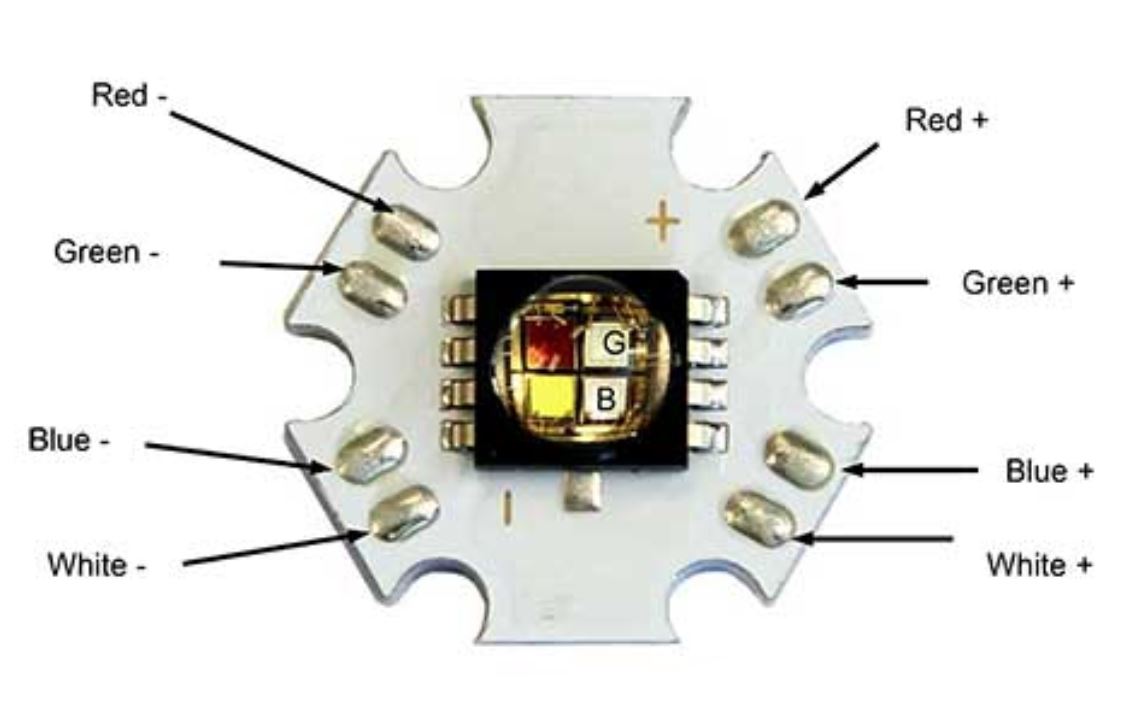

High power light-emitting diodes (LED)

can use 350 milliamps or more in a single LED. Most of the electricity in an LED becomes heat rather than light (about 70% heat and 30% light). If this heat is not removed, the LEDs run at high temperatures, which not only lowers their efficiency, but also makes the LED less reliable. Thus, thermal management of high power LEDs is a crucial area of research and development. It is necessary to limit the junction temperature to a value that will guarantee the desired LED lifetime.

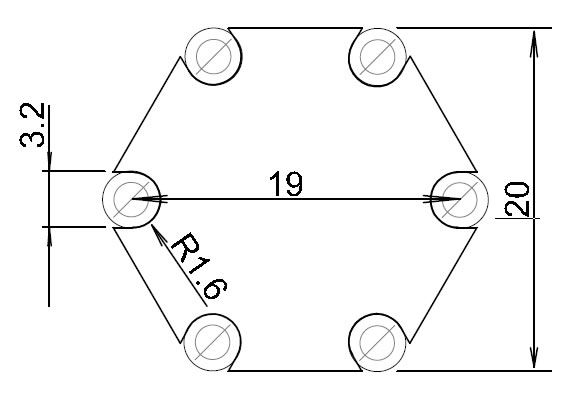

Star Metal Core Printed Circuit Board (Star MCPCB)

are boards with 20 mm dimension of 6-sided polygon witch incorporate a base metal material as heat spreader as an integral part of the circuit board. The metal core usually consists of aluminum alloy. Furthermore MCPCB can take advantage of incorporating a dielectric polymer layer with high thermal conductivity for lower thermal resistance.

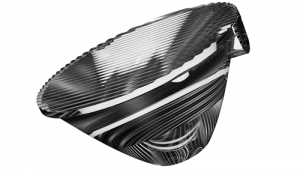

Spot Optics & Holders

Carclo Technical Plastics (CTP) is a leading manufacture of molded poly-carbonate lens systems used to control optical properties with Cree and Luxeon LEDs.Manufactured in lens quality poly-carbonate, the Carclo Total Internal Reflection (TIR) optics have much higher temperature resistance than acrylic optics and carry a UL rating.

These one piece optics are tough and impact resistant, but precautions should be taken to prevent them from coming in contact with organic solvents or vapor.

LED optics control your illumination pattern, either diffusing it or focusing it as your application requires.

Popular illumination patterns are: tight spot, medium spot, wide spot and elliptical spot.